Diamond is one of the hardest materials on the planet, but scientists have found a new way of getting it to bend and deform – and the key to these processes is to work at the tiniest possible scales.

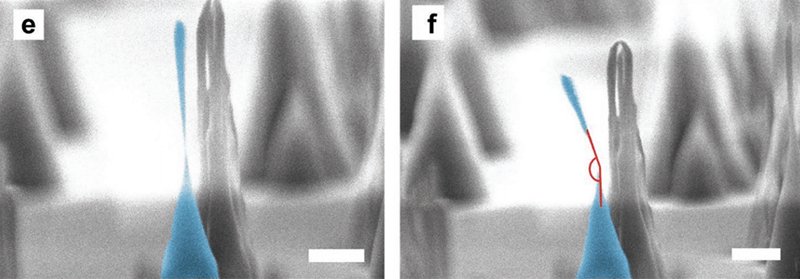

By beaming an electric field at diamond nanoneedles just 20 nanometres in length (about 10,000 time smaller than a human hair), the researchers were able to get them to bend to 90 degrees without fracturing.

A scanning electron microscope was used for the pushing job, which doesn’t lead to any damage or defects in the diamond, but does produce enough electrostatic charge for the needles to bend over. The process is reversible, too.

This remarkable achievement could have a range of applications for how diamond is used – in storing energy, for example, or in protective materials, or even in quantum computing – but the researchers say that their work also warns about potential challenges for nanotechnology.

“Diamond is the frontrunner for emerging applications in nanophotonics, microelectrical mechanical systems and radiation shielding,” says material scientist Blake Regan, from the University of Technology Sydney (UTS) in Australia.

“We need to know how these materials behave at the nanoscale – how they bend, deform, change state, crack. And we haven’t had this information for single-crystal diamond.”

Regan and his colleagues are interested in how the mechanical properties of materials can change when you’re dealing with very small samples of them; they ran molecular dynamics simulations alongside their experiments to analyse the underlying mechanisms.

As well as bending the diamond nanoneedles forwards and backwards, the researchers also observed a new type of plastic deformation, where the needles didn’t bend back. This only came about when the dimensions of the nanoneedles and the orientation of the diamond crystals were set in a very specific way.

The team also discovered a new hypothetical state of carbon through their simulations, which they have called O8-carbon: it appears as diamond is put under strain, with bonds progressively breaking like a zipper.

All of these discoveries are very useful both in the study of diamond and in the study of nanotechnology in general. Getting cuts of diamond down to this size isn’t easy at the moment, but could have many potential uses in the future.

The researchers behind the latest study aren’t the first to figure out how to bend diamond without it snapping: similar results published two years ago also involved diamond nanoneedles, though they were created and tested using different processes.

“These are very important insights into the dynamics of how nanostructured materials distort and bend, and how altering the parameters of a nanostructure can alter any of its physical properties from mechanical to magnetic to optical,” says physicist Igor Aharonovich from UTS.

“The potential applications of nanotechnology are quite diverse. Our findings will support the design and engineering of new devices in applications such as super-capacitors or optical filters or even air filtration.”

The research has been published in Advanced Materials.

Photographer Finds Locations Of 1960s Postcards To See How They Look Today, And The Difference Is Unbelievable

Photographer Finds Locations Of 1960s Postcards To See How They Look Today, And The Difference Is Unbelievable  Hij zet 3 IKEA kastjes tegen elkaar aan en maakt dit voor zijn vrouw…Wat een gaaf resultaat!!

Hij zet 3 IKEA kastjes tegen elkaar aan en maakt dit voor zijn vrouw…Wat een gaaf resultaat!!  Scientists Discover 512-Year-Old Shark, Which Would Be The Oldest Living Vertebrate On The Planet

Scientists Discover 512-Year-Old Shark, Which Would Be The Oldest Living Vertebrate On The Planet  Hus til salg er kun 22 kvadratmeter – men vent til du ser det indvendigt

Hus til salg er kun 22 kvadratmeter – men vent til du ser det indvendigt  Superknepet – så blir snuskiga ugnsformen som ny igen!

Superknepet – så blir snuskiga ugnsformen som ny igen!  Meteorite That Recently Fell in Somalia Turns Out to Contain Two Minerals Never Before Seen on Earth

Meteorite That Recently Fell in Somalia Turns Out to Contain Two Minerals Never Before Seen on Earth  Nearly Frozen Waves Captured On Camera By Nantucket Photographer

Nearly Frozen Waves Captured On Camera By Nantucket Photographer  It’s Official: Astronomers Have Discovered another Earth

It’s Official: Astronomers Have Discovered another Earth